With over 38 years of experience, TAGONG is the expert in manufacturing standard fasteners and special fasteners

+86 15160779301

+86 18906098857

Understanding DIN6330 ISO4033 High Nuts and Long Nuts for U-Bolts

2025-12-20

When it comes to fastening applications in industrial settings, DIN6330 ISO4033 high nuts and long nuts play a crucial role, especially when used in conjunction with U-bolts. Understanding the specifications and benefits of these components can significantly enhance the effectiveness of your fastening solutions.

DIN6330 refers to a standard that outlines the dimensions and mechanical properties of high nuts, while ISO4033 specifies the criteria for long nuts. High nuts are characterized by their increased height, which facilitates the use of longer threaded rods or bolts, providing enhanced load distribution. This is particularly beneficial in applications where stability and strength are paramount, such as in machinery and structural assemblies.

Long nuts, on the other hand, offer the advantage of accommodating greater thread engagement. This is essential for applications where traditional nuts may not provide sufficient clamping force. By utilizing long nuts with U-bolts, you can effectively secure components together, ensuring that they remain tightly fastened even under dynamic loads.

Both DIN6330 and ISO4033 nuts are typically made from high-strength materials, which enhance their durability and resistance to corrosion. Common materials include carbon steel and stainless steel, each offering unique properties that suit different environmental conditions. For instance, stainless steel is preferred in corrosive environments due to its excellent resistance to oxidation and rust, while carbon steel may be chosen for its tensile strength in dry environments.

When selecting high nuts or long nuts for U-bolts, it’s essential to consider factors such as the load requirements, the environmental conditions, and compatibility with other fasteners. The proper selection ensures that the assembly can withstand the intended mechanical stresses without failure.

In terms of installation, it’s important to apply the correct torque while fastening these nuts. Insufficient torque can lead to loosening under vibration, while excessive torque can result in stripping the threads or damaging the components. Utilizing a torque wrench can help achieve the optimal tightness required for reliable performance.

In summary, DIN6330 ISO4033 high nuts and long nuts are indispensable components in the fastener industry, especially when used with U-bolts. Their design and material properties are tailored to meet the rigorous demands of various applications, making them a reliable choice for professionals looking to enhance their fastening solutions. By understanding the nuances of these nuts, you can make informed decisions that improve the safety and efficiency of your assemblies.

DIN6330 refers to a standard that outlines the dimensions and mechanical properties of high nuts, while ISO4033 specifies the criteria for long nuts. High nuts are characterized by their increased height, which facilitates the use of longer threaded rods or bolts, providing enhanced load distribution. This is particularly beneficial in applications where stability and strength are paramount, such as in machinery and structural assemblies.

Long nuts, on the other hand, offer the advantage of accommodating greater thread engagement. This is essential for applications where traditional nuts may not provide sufficient clamping force. By utilizing long nuts with U-bolts, you can effectively secure components together, ensuring that they remain tightly fastened even under dynamic loads.

Both DIN6330 and ISO4033 nuts are typically made from high-strength materials, which enhance their durability and resistance to corrosion. Common materials include carbon steel and stainless steel, each offering unique properties that suit different environmental conditions. For instance, stainless steel is preferred in corrosive environments due to its excellent resistance to oxidation and rust, while carbon steel may be chosen for its tensile strength in dry environments.

When selecting high nuts or long nuts for U-bolts, it’s essential to consider factors such as the load requirements, the environmental conditions, and compatibility with other fasteners. The proper selection ensures that the assembly can withstand the intended mechanical stresses without failure.

In terms of installation, it’s important to apply the correct torque while fastening these nuts. Insufficient torque can lead to loosening under vibration, while excessive torque can result in stripping the threads or damaging the components. Utilizing a torque wrench can help achieve the optimal tightness required for reliable performance.

In summary, DIN6330 ISO4033 high nuts and long nuts are indispensable components in the fastener industry, especially when used with U-bolts. Their design and material properties are tailored to meet the rigorous demands of various applications, making them a reliable choice for professionals looking to enhance their fastening solutions. By understanding the nuances of these nuts, you can make informed decisions that improve the safety and efficiency of your assemblies.

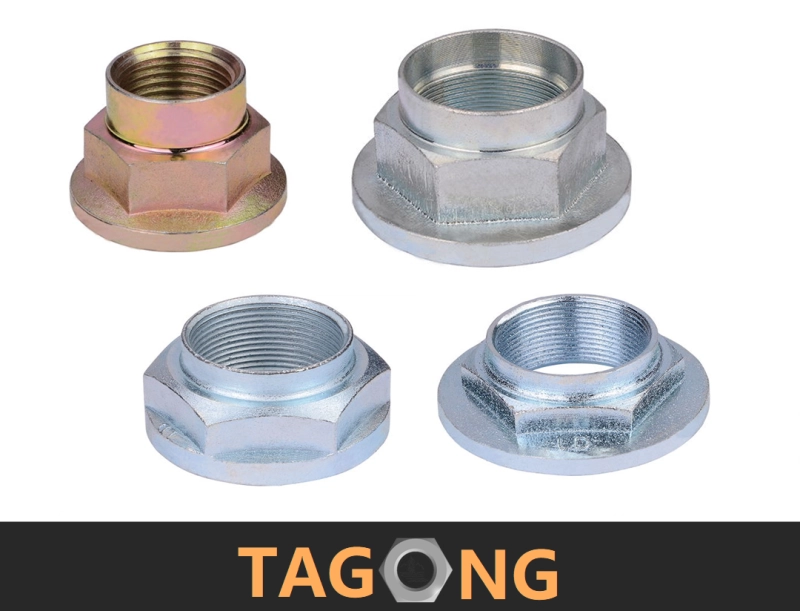

DIN6330 ISO4033 High Nuts Long Nuts for Ubolts

RELEVANT INFORMATION

Understanding DIN6330 ISO4033 High Nuts and Long Nuts for U-Bolts

When it comes to fastening applications in industrial settings, DIN6330 ISO4033 high nuts and long nuts play a crucial role, especially when used in conjunction with U-bolts. Understanding the specifications and benefits of these components can significantly enhance the effectiveness of your fastening solutions.

DIN6330 refers to a standard that outlines the dimensions and mechanical properties of

2025-12-20

The Science Behind Flange Nut Design and Functionality: A Comprehensive Guide

The Science Behind Flange Nut Design and Functionality

Introduction to Flange Nuts

Flange nuts are integral components used in various industrial applications, primarily known for their unique design that enhances performance in fastening systems. These nuts provide increased load-bearing capabilities and improved resistance against loosening. To understand their significance, we must delve into t

2025-12-15

The Essential Role of Railway Fasteners in Modern Rail Systems

In the realm of industrial equipment and components, railway fasteners play an indispensable role in the integrity and functionality of rail systems. These fasteners are critical for securely fastening tracks, switches, and other structural elements of rail infrastructure. Their importance cannot be overstated, as the safety and efficiency of rail transport fundamentally depend on the reliability

2025-12-10