With over 38 years of experience, TAGONG is the expert in manufacturing standard fasteners and special fasteners

+86 15859750876

+86 13599720777

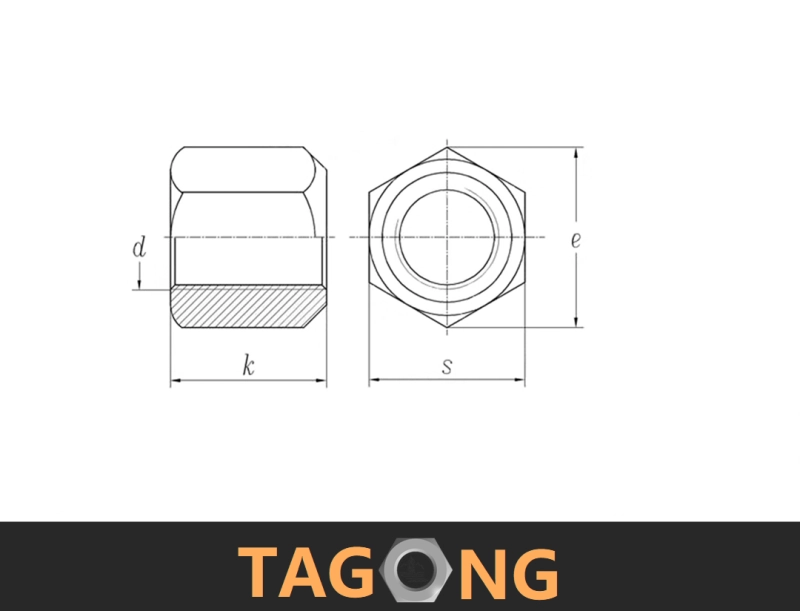

DIN6330 ISO4033 High Nuts Long Nuts for Ubolts

Categories:

Keyword:

Standard fasteners

DIN6330 ISO4033 High Nuts Long Nuts for Ubolts

Product introduction

Jinjiang Tagong Hardware Forging Manufacturer Co. LTD,

Specializing in the production of nuts since 1985,

Standard nuts (GB/DIN/ISO/UNI/JIS/GOST/ANSI/ASTM);

Special nuts (slotted nuts, nylon insert nuts, flange nuts, self-locking nuts, square nuts, cap nuts, etc.)

Property class, Material, and Surface coating can be replaced as below :

| Mechanical Property | Material | Surface Treatment |

| Class 4 / 5/ 6/ 8/ 10/ 12 | Steel 45 40Cr 35CrMo 42CrMo Q235 Steel20 |

Plain Black oxide Zinc Plated Phosphate Dacromet Geomet HDG |

Packing way: 25kg/carton, 1.5 tons-2.5 tons/pallet; or as requested by the buyer.

If you want to know more information, pls contact with us.

P.S.: Please contact us to re-quote the exact price before placing an order, because the material price is unstable.

DIN6330 ISO4033 High Nuts Long Nuts for Ubolts are high-strength fasteners specifically designed for U-bolts, widely used in mechanical equipment, construction projects, vehicles, and other fields. They are precision-machined from high-quality alloy steel, possessing exceptional durability and compressive strength, capable of withstanding heavy loads and complex working environments. The design of these high nuts not only ensures reliable fastening but also effectively extends the service life of U-bolts, guaranteeing installation stability and safety.

These high nuts feature a standard hexagonal structure, providing excellent grip and tightening performance, making installation and removal easy for users. The moderate length of the long nuts provides a larger contact area during fastening, increasing the load capacity of the bolt and effectively distributing stress, preventing damage caused by excessive localized stress. Their unique design ensures even distribution of fastening force, greatly improving the stability of equipment during long-term use, preventing loosening, and ensuring safety during operation.

These high nuts comply with DIN6330 and ISO4033 international standards, possessing high precision, high strength, and corrosion resistance, making them suitable for use in various harsh environments. Whether in high temperatures, low temperatures, or humid and corrosive environments, these long nuts maintain excellent performance, preventing loosening or corrosion problems caused by environmental factors. They are widely used in various industries, including industrial, agricultural, automotive manufacturing, and construction, and are particularly suitable for fastening applications requiring high load capacity and high safety.

When purchasing these high nuts, you can choose different specifications and sizes according to your actual needs to ensure compatibility with U-bolts. Their design is simple yet powerful, making them an indispensable component in any project requiring high-strength fasteners. Whether for machine equipment maintenance or new engineering projects, DIN6330 and ISO4033 high nuts provide robust and reliable support for your equipment, ensuring that every connecting component is secure and preventing any safety hazards caused by loose bolts.

With their excellent quality, reliable performance, and flexible application range, DIN6330 ISO4033 High Nuts Long Nuts for Ubolts have become the preferred standardized fasteners in many industries. It not only provides strong fastening force but also effectively enhances the overall safety and durability of the equipment, making it an indispensable key component for equipment installation and maintenance.

Our Factory Introduction

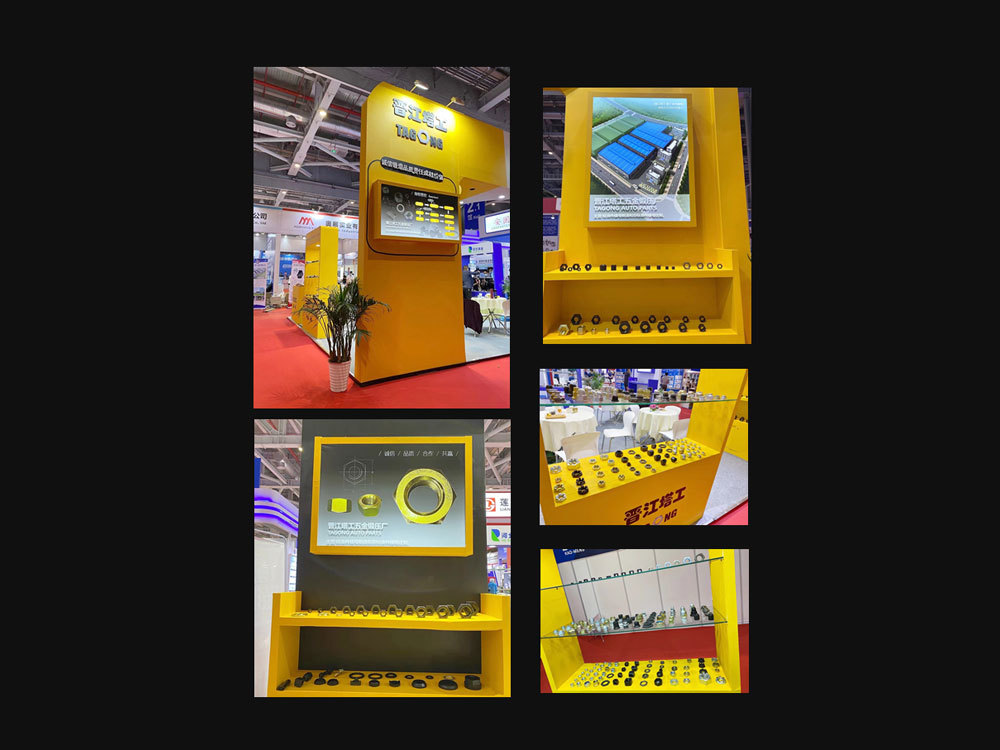

With over 38 years of manufacturing experience, Tagong is an expert in the manufacturing of standard and special fasteners.

Founded in 1985, we have established an advanced manufacturing factory covering an area of 60,000 square meters in Jinjiang City.

With a production system that combines forging and high-precision machining, a professional production management team, and a senior technical R&D department, we can according to the customer's unique specifications and drawings produce special fasteners.

Our products have passed ISO9001/2015, GB/T19001-2016, and SGS certificate testing and certification.

Our passion for excellence has driven us to become a global supplier. Our products have been exported to Europe, Australia, North America, South Asia, and other places, and are well received by customers.

Development History

Development History

Technical Equipment

Exhibition Show

Next:

ONLINE CONSULTING

RELATED PRODUCTS